A Novel Net-work Framework Proposed for Operation State Prediction and Management

A Novel Net-work Framework Proposed for Operation State Prediction and Management

Researchers propose a multivariate time-series prediction framework that is based on deep hybrid network in which they introduce innovatively noise elimination technology into deep learning modeling.

Industrial process systems operate normally somewhere around us. But do you know what is happening inside them? Scientists and engineers know clearly about the hidden complex that physical-chemical reactions, heat-mass transfer, and thermal-hydraulic processes are taking place every second. Actually, for years, research people have been trying in different ways to monitor, to diagnose and to predict just for a normal and safe operation.

However accurate prediction is no walk in the park at any situation, not to speak of those giant and complicated systems. With rapid growing of Artificial Intelligence technology, soft measurement rises to cope, which collects data from neighboring somewhere, considering after all some data cannot be obtained directly, to figure out a result after inputting those indirect data into modeling.

“So, when it comes to modeling and calculation, data is vital,” explained YAO Yuantao who is a research fellow of GE Daochuan’s group with Hefei Institutes of Physical Science under CAS and is also the first author of the paper that reported the work of their collaboration with XIE Min from City University of Hong Kong.

“When we were targeting the accuracy, first we have to figure out what is there to bring uncertainty. We found the specific noise,” YAO talked about what their study started with.

The team found that the specific noise generated by different component monitors that are applied in system operation to collect data cause uncertainty of the data and then prediction accuracy is reduced as a result.

“We focused our work on how to remove data uncertainty caused by noise inside,” YAO continued to elaborate how they approach the problem.

They proposed a deep hybrid network-based multivariate time-series prediction framework that includes three modules working together to obtain certain crucial monitored industrial process safety metrics.

“We built module for parameter variable selection, then feature selection function for input monitoring process data can be realized.” YAO described the modules they integrated into their framework.

Besides the module for parameter variable selection, they also set up a residual elimination module with a convolution structure to eliminate the data noise uncertainty and a prediction module with a time-distributed GRU for trend prediction of the monitored index.

The three modules offer collectively a combination of data noise uncertainty elimination and time-series prediction. It can effectively reduce the uncertainty caused by different degrees and types of noise.

Furthermore, it will help to improve the prediction performance by utilizing the redundant information in the same type of monitoring data between adjacent nodes.

“It is largely due to the residual elimination design in the framework,” said YAO “We tested it on the proposed nuclear platform dataset benchmark and the results turned out to be good.”

This work, believed by the team, can provide a reference for other industrial process systems.

This research has been supported by the National Natural Science Foundation of China (71971181), the Postdoctoral Science Foundation of China (2022M713186), and the Research Grant Council of Hong Kong (11203519 and 11200621).

Fig. 1 Schematic of the designed, deep hybrid network-based prediction framework.

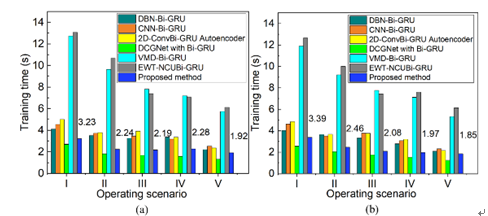

Fig. 2 Comparison of training time ((a) Core inlet temperature; (b) SG outlet temperature).