Ce Improves Corrosion Resistance of China Low Activation Martensitic Steel

According to a recent research published in Corrosion Science, scientists improved the corrosion resistance of China Low Activation Martensitic (CLAM) steel to lead-bismuth eutectic (LBE) with applying rare earth element Ce.

The research was conducted by Prof. HUANG Qunying’s team from The Institute of Nuclear Energy Safety Technology, Hefei Institutes of Physical Science Chinese Academy of Sciences.

Lead-cooled Fast Reactor (LFR) with LBE is expected to be widely used as the main coolant in many areas. However, LBE corrosion, together with strong radiation and high temperature, would affect the lifetime of structural material for LFR. Therefore it is necessary to control the dissolved oxygen concentration in LBE to improve its corrosion resistance.

CLAM steel is a candidate structural material for LFR. The rare earth element Ce tends to segregate at the grain boundary and improve the stability of the grain boundary, so its application in steel has been widely studied recent years. However, it is unclear whether it can help to improve the LBE corrosion resistance of structural material.

In this study, the research team carried out experimental studies on the corrosion behavior of CLAM and Ce-CLAM specimens under the LBE environment with a dissolved oxygen concentration of 10-6 wt% at 500 ℃.

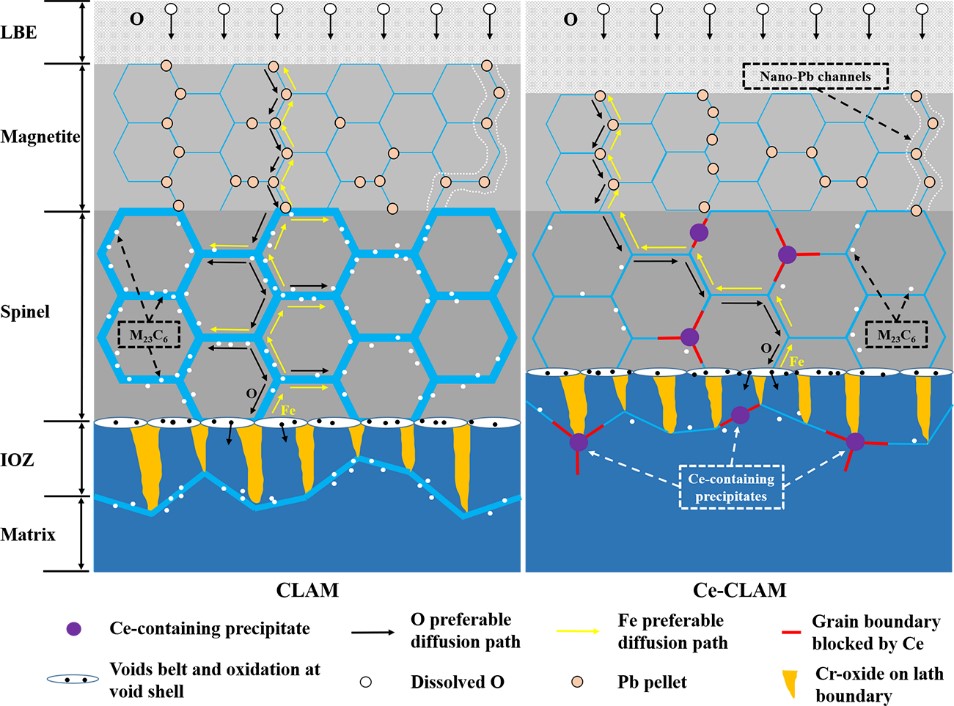

They found that Ce mainly existed at grain boundary, effectively reduced the number of M23C6 and the Cr-poor area near grain boundary, and enhanced the stability of grain boundary.

With the increase of exposure time, the thickness of oxide scale on the surface of the two kinds of specimens gradually increased. The growth rate constant kp of oxide scale of Ce-CLAM was about 1/2 of that of CLAM, which indicates that the addition of minor Ce improved the LBE corrosion resistance of CLAM steel.

Based on the above results, they proposed the mechanism model that Ce element enhanced corrosion resistance of CLAM steel in LBE.

The related results will provided experimental data and theoretical reference on the optimization design of LBE corrosion resistance for structural material of LFR.

This work was funded by the National Key R&D Program of China, the Youth Innovation Promotion Association of Chinese Academy of Sciences (CAS) and the International Partnership Program of CAS.

Fig. 1 Microstructures of CLAM and Ce-CLAM specimens before exposure (Image by LUO Wenwei)

Fig. 2 Typical surface and cross-sectional morphologies for CLAM and Ce-CLAM after exposure (Image by LUO Wenwei)

Fig. 3 Mechanism of Ce on corrosion resistance for CLAM steel in LBE (Image by LUO Wenwei)