Advancing High Entropy Alloys Designed for Nuclear Energy Systems

Advancing High Entropy Alloys Designed for Nuclear Energy Systems

A team led by Prof. ZHENG Mingjie from Institute of Nuclear Energy Safety Technology(INEST),Hefei Institutes of Physical Science (HFIPS) of Chinese Academy of Sciences (CAS) recently reported accelerated design of low-activation high entropy alloys with desired phase and property by machine learning.

This work was published as a cover article in Applied Materials Today.

Low-activation high-entropy alloys (HEAs) show promise as candidate structural materials for advanced nuclear energy systems due to their superior mechanical properties and radiation resistance. However, the vast composition space of HEAs presents challenges in design. Traditional methods fall short in meeting HEA composition requirements, while existing machine learning models focus either on phase structure or performance prediction. A holistic approach integrating phase structure and performance design is crucial for efficient design of HEAs in the future.

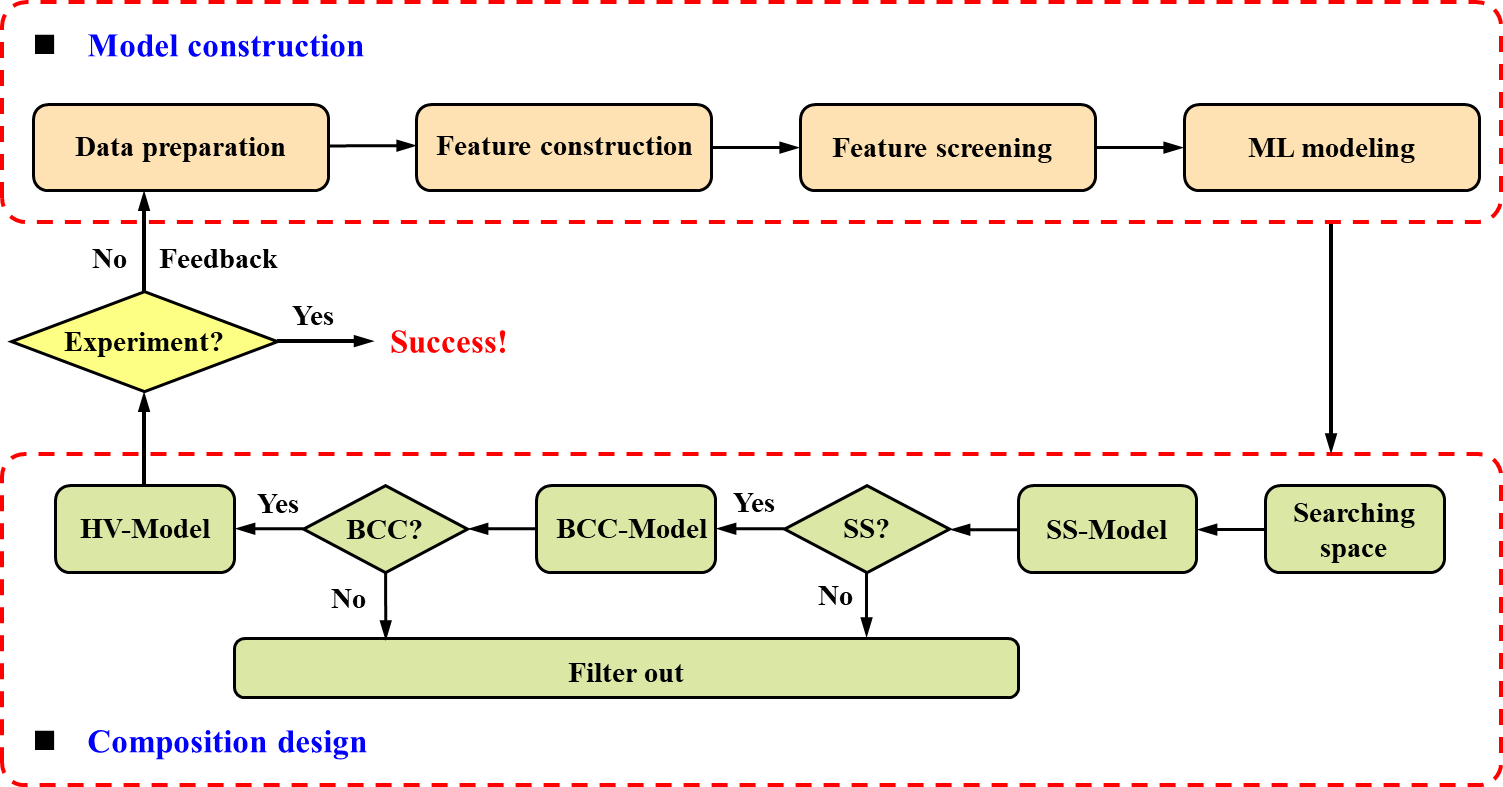

In this research, the team proposed an integrated design strategy based on the machine learning (ML) method, by which a new single-phase body-centered cubic (BCC) low-activation HEA (Fe35Cr30V20Mn10Ti5) was obtained.

Scientisits developed two accurate classification models to identify single-phase BCC solid-solution HEAs, with an accuracy above 85%. They also created a regression model with a high correlation coefficient to predict the hardness of HEAs. By combining these models, they successfully identified low-activation HEAs with the desired phase and properties. Using this approach, a new single-phase BCC low-activation HEA (Fe35Cr30V20Mn10Ti5) with a hardness measurement of 555.9 ± 15.3 HV was designed and fabricated, meeting the design requirements. The effectiveness of the integrated design strategy was confirmed through experiments.

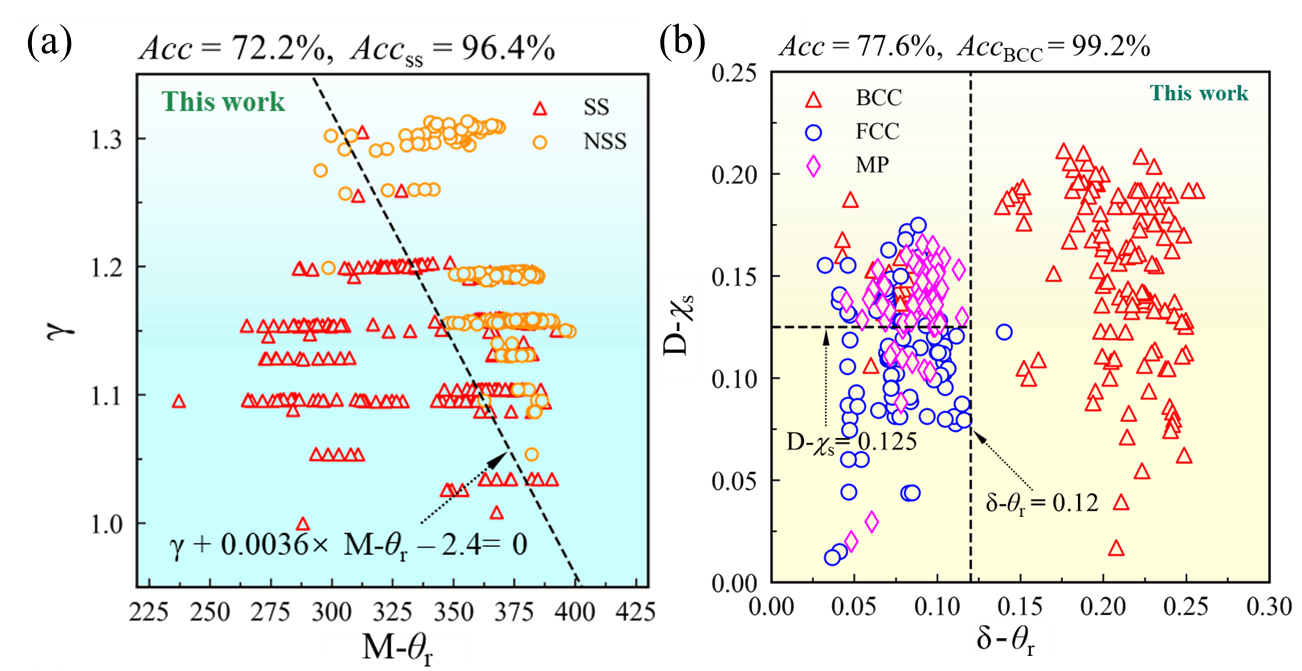

Additionally, they introduced two new phase selection rules with accuracy exceeding 95% to efficiently screen single-phase solid-solution and BCC HEAs.

This work demonstrates the successful application of an integrated design strategy based on machine learning for the efficient design of low-activation HEAs. The approach holds promise for extending integrated design principles to other advanced materials for optimal structure and performance.

Figure 1. Current Cover of Applied Materials Today. (Image by LI Xiaochen)

Figure 2. An integrated design strategy for low-activation HEAs by ML method. (Image by LI Xiaochen)

Figure 3. Statistical analysis results using new phase selection rules. (Image by LI Xiaochen)