Researchers Realize Strong Bonding Between China Low Activation Martensitic Steel and Oxide Dispersion Strengthened Alloy

Recently, a research team led by Prof. HUANG Qunying from the Hefei Institutes of Physical Science of the Chinese Academy of Sciences, together with the Shenyang National Laboratory for Materials Science, has successfully achieved almost defect-free bonding between China low activation martensitic (CLAM) steel and oxide dispersion strengthened (ODS) alloy via the hot compression bonding (HCB) method.

The optimized process produced joints with tensile strength comparable to that of the CLAM base material, demonstrating excellent structural integrity and performance.

These findings have been published in Materials Characterization.

CLAM steel and 9Cr-ODS alloy are key structural materials for fusion reactors. CLAM steel has mature fabrication technology and its upper service temperature is 550°C, while the 9Cr-ODS alloy exhibits superior high-temperature strength and irradiation resistance owing to its nano-oxide dispersions. However, large-scale production of the ODS alloy remains challenging, and conventional welding methods often cause coarsening or dissolution of these nano-oxides, weakening joint performance. Therefore, developing a reliable bonding technique between the two materials is essential for fabricating durable, high-temperature fusion blanket components.

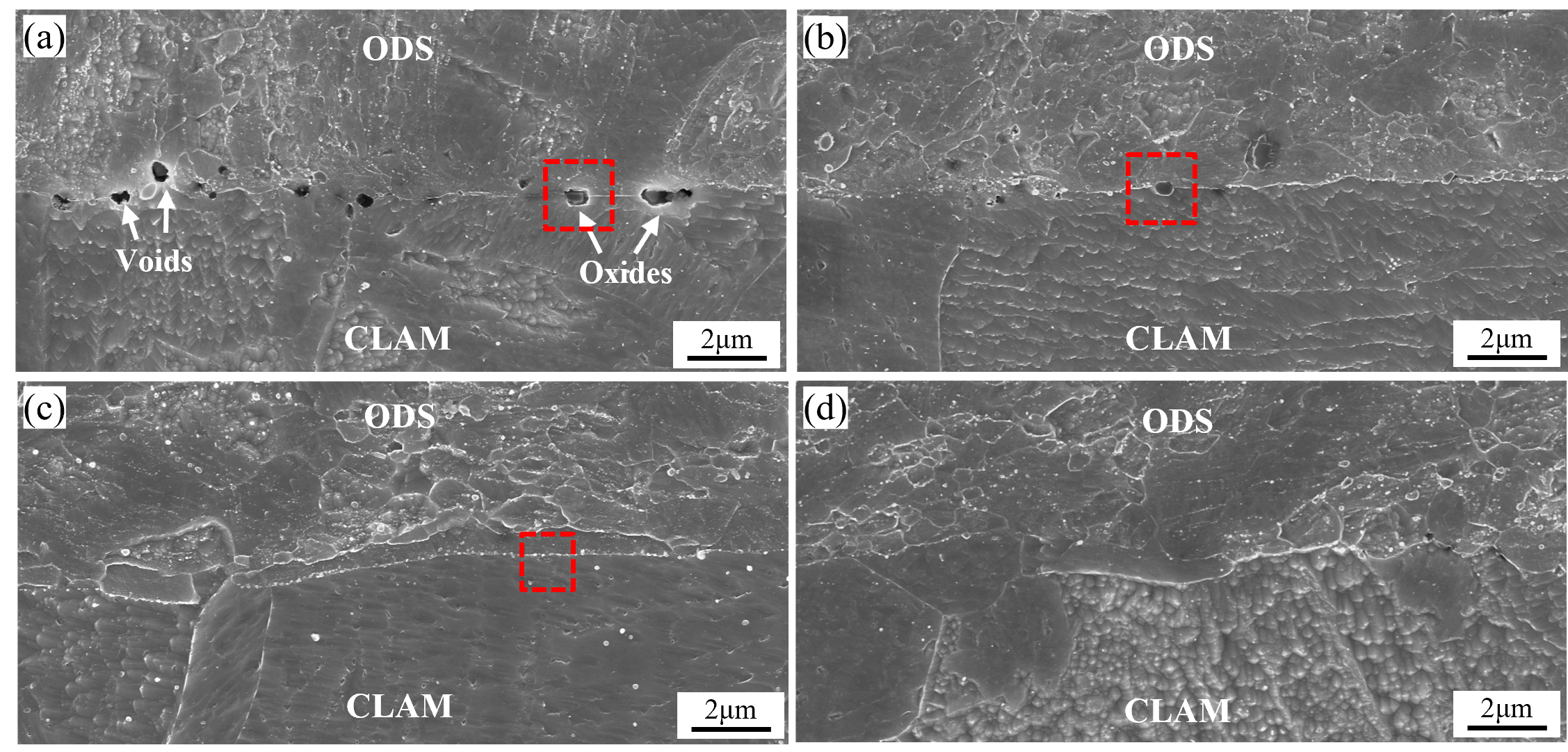

In this study, the team applied the HCB method at 1050 °C to examine how varying levels of deformation affect the interfacial microstructure and oxides at the interface of the bonded materials. The results show that with increasing deformation, the coarse oxides rich in chromium and manganese gradually decompose and transform into fine nanoscale particles such as TiTaO₄ and Y₂TiO₅. As deformation proceeds, the joint strength approaches that of the base CLAM steel, core–shell structured oxides emerge, and the original flat interface evolves into dynamically recrystallized grains, leading to complete interfacial healing.

This research elucidates the transformation pathway of interfacial oxides and the microstructural healing mechanism during HCB, according to the team.

This study was supported by the National Natural Science Foundation of China, the International Partnership Program of the Chinese Academy of Sciences, and the CNNC Science Fund for Talented Young Scholars.

Interfacial microstructures near the interface compressed at 1050 °C with different deformations:

(a) 5%, (b) 10%, (c) 30%, (d) 50%. (Image by BAI Yunfei)

(a) STEM image near the interface with 30% deformation; (b) enlarged view in the black region of (a); (c) corresponding EDS map; (d) HRTEM of OP3;

(e-f) enlarged view of HRTEM in the red region of (d) and corresponding FFT image. (Image by BAI Yunfei)